Basically, scrap metal is divided into two parts i.e. ferrous and nonferrous. Metals are wildly used in our everyday life for instance- in making cars, trucks, trains, train tracks, ships, airplanes, whitegoods, cutlery, pots, and pans. They are recyclable and metal dealers are desperate to purchase it for top prices. Moreover, steel is 100% recyclable metal but for all this process you should be experts and safe in recycling.

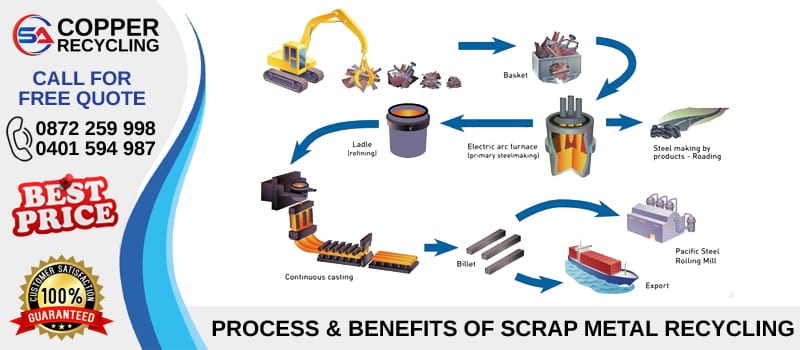

The Process of Metal Recycling

If the non-ferrous metal has steel or iron component in it then, it is treated as scrap metal. Scrap yards recycling centre buys such unwanted metals for recycling purposes in which they are shredded and then melted in furnaces at high temperatures. Blocks, ingots, or sheets are produced for selling it to manufactures. The recycling Process comprises of Four stages mention below-

Collection and Sorting-

The first main step in the recycling process is to collect all metal products. The items of scrap metal recycling include whitegoods, roller shutters, bicycles, radiators, steel or alloy wheels and batteries and even though, you can recycle steel kitchen sink. Recyclers pay high prices for scrap metals.

Crushing and Shredding-

In this step, recyclers crush the metal in compactors for handling it on conveyor belts easier. When the hammer melts and then shred the metal into pieces.

Separation-

Now it’s high time to place the shredded metal into magnetic drums for separating the ferrous and non-ferrous metals. The paint & Plastic i.e. non-metallic material will be removed through blowing hot air.

Melting and Purification-

The last step is to melt the scrap metal into large furnaces. Every metal has a special furnace design based on its properties. However, furnaces contain fuel-efficient regenerative burners in order to reduce their impact on the environment.

In a molten state, metals are further purified by ‘Eddy current’ electrolysis. In spite of the energy costs utilized in salvaged material reusing, the energy required is less for this situation as contrasted and the creation from crude material.

Making steel from reused jars for instance utilizes 75% less energy than when creating steel from crude materials. Australia has around 90% reuse rate for steel items burned-through, with each ton of reused steel sparing 1130kg of iron metal, over 630kg of coal, and 54kg of limestone from being mined.

Benefits of Recycling Scrap Metal

There are several benefits of recycling scrap metal. It conserves our natural resources, reduces greenhouse gasses, reduces landfills or dumping of metals in landfills, and most important is saving of substantial energy made from recycling scrap metals. If you want to recycle your scrap metal and curious to get the top price for it then, you can contact SA Copper Recycling at 0401 594 987…